FACILITIES

Microscopy / Spectroscopy

Scanning Electron Microscope (SEM) / Taramalı Elektron Mikroskobu

A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that contain information about the surface topography and composition of the sample.

Click to visit instrument website for technical specifications.

Optıcal Mıcroscope / Optik Mikroskop

The optical microscope in TEMAG Laboratories is capable of taking pictures in magnifications of 5x, 10x, 20x, 50x and 100x. The microscope is used for polarized images, also for microbiological images with the use of immersion oil.

Click to visit instrument website for technical specifications.

UV-Vis Spectroscope / UV-vis Spektroskobu

The research-grade spectrophotometer is used in a wide range of fields, and easily expanded to suit the measurement objective. Transmitance, absorbance and reflectance properties of the samples can be easily taken.

It can be possible to make these analyses for powder and thin film samples.

Click to visit instrument website for technical specifications.

Nanofibers and Filtration

Filter Tester / Filtre Test Santrali

The filter testing equipment is used for measuring whether the filter media is convenient to standards. The testing standards of the device are:

- EN 1822-3

- ISO 11155-1

- EN779 / ASHRAE 52.2

- EN 149: 2001

- 42 CFR 84

AIR PERMEABILITY TESTER / Hava geçirgenliği test cihazı

It is used to determine the air permeability of all kind of fabrics including industrial fabrics and fabrics without texture. 20 cm² sample holders are supplied with the device as a standard. Possibility of decreasing pressure up to 500 pa. Air permeability is saved as dm³/min.

Click to visit instrument website for technical specifications.

Vıscosımeter / Viskozite Ölçer

For nanofiber and polymer studies, viscosity is a critical parameter for determining properties of the end-product. The viscometer instrument is used for proper measurement of solution/solvent viscosities.

Click to visit instrument website for technical specifications.

Electrospınnıng Devıce / Elektroüretim Cihazı

Electrospinning device for production of nanofiber membranes. The device allows bottom-up spinning with one or multiple nozzels. It has a rotating collector with horizontal movement that allows production of homogenous fibrous samples.

Applications: electrospinning of nanofiber membranes for textile, filtration, biomedicine, medicine, chemical industry, construction, etc.

Click to visit instrument website for technical specifications.

Aerospınner solutıon blowıng system / çözeltiden üfleme sistemi

AeroSpinner is a solution blow spinning system. The system uses compressed air for producing nanofibers from polymer solutions via concentric nozzle in which the solution passes through inner nozzle and the air through outer one.

Click to visit instrument website for technical specifications.

Aerospınner electro blowıng system / elektro üfleme sistemi

The electro-blowing system is a hybrid system capable of producing nanofiber with electro-spinning, electro blowing, and solution blow spinning method.

Click to visit instrument website for technical specifications.

Nanocentrıno centrifugal spinning system / santrifüjlü eğirme sistemi

Centrifugal spinning system is another nanofiber production system that uses centrifugal forces to surpass polymer solution surface tension with use of high speed rotating spinneret.

Composites - Plastics - Synthetic Fibers

Extruder / Ekstrüder

20-cm-width film, ⌀1.75 mm filament

Extruder is a device to melt polymer materials that are in granule form. The polymer is heated step by step and melted under pressure. Material moves between a barrel and screw through a die to shape the molten polymer. Screw geometry changes with type of polymer.

Click to visit instrument website for technical specifications.

Compounder

The compounder is used for preparation of thermoplastic composites, masterbatch, green composites, nanocomposites, filaments and polymer blends.

Click to visit instrument website for technical specifications.

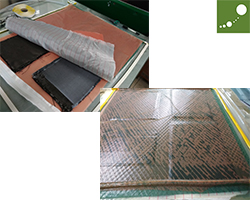

Vacuum Assisted Resin Transfer Moulding (VARTM) / Vakumlu Reçine Transfer Sistemi

The vacuum-assisted resin transfer molding (VARTM) is used to produce laminated composite materials. The resin is transferred from one side of the stacked reinforcing fabrics through the other side with the help of vacuum pump, and the system has hot surface to set the curing process of resin.

Figure: VARTM method demonstration (a) side view; (b) top view

Fılament Wındıng / Elyaf Sarım

This fabrication process involves winding filaments under tension over a rotating mandrel. The machine is capable of building parts up to 0.25” (7 mm) in thickness, or as thin as 0.015" (0.40 mm) wall thickness and mostly up to 20 feet long along with different kind of mandrels (2 axis & 4 axis) under different curing temperatures.

Melt Spinner / eriyikten çekim

Hopper capacity is 5lt. The extruder can be heated upto 280 °C. The barrel capacity is ca. 150 gr. The spin pack has monofilament and multifilament dies with 4, 8, 36 and 71 holes. PP, HDPE, LLDPE and PA can be processed.

Click to visit instrument website for technical specifications.

Melt Flow Index / erime akış indeksi

Melt Flow Index measures flow rate of thermoplastic polimer that is under certain temperature and load. The value indicates thermoplastic viscous flow characteristic under melt condition.

Click to visit instrument website for technical specifications.

Microbiology

Sterilizer / Otoklav

The vaporous sterilizer is a device used for dentistry, medicine and laboratory. There are two standards for sterilization.The pressure occurs inner chamber which has distilled water due to high temperature. It is used to kill bacteria 121°C / 15 min/atm in the lab.

Click to visit instrument website for technical specifications.

Centrifuge / Santrifüj

The centrifuge is ideal for seperating the supernatant from precipitate with effect of centrifugal force.

Click to visit instrument website for technical specifications.

Freeze Dryer / Liyofilizatör

The freeze dryer provides the drying of the product by freezing the product in solution or suspension and then removing the gas phase formed by sublimation. There are 6 manifold stainless steel vacuum towers to work with balloon joints and glass containers of different diameters and sizes.

Click to visit instrument website for technical specifications.

Li-Ion and Solar Cells

Glove Box / Eldivenli Kabin Sistemi

The glove box is a sealed container that is designed to allow one to manipulate objects where a separate atmosphere is desired. The gloves arranged in such a way that the user can place their hands into the gloves and perform tasks inside the box without breaking containment.

Click to visit instrument website for technical specifications.

Carbonızatıon Furnace / Karbonizasyon Fırını

Three zone tube furnace for high temperature treatment of different types of materials. The high temperature treatments can be done under controlled atmosphere (argon, nitrogen, oxigen…) during prolonged period of time.

Applications: carbonization organic samples, sintering and annealing of ceramic and inorganic materials.

Click to visit instrument website for technical specifications.

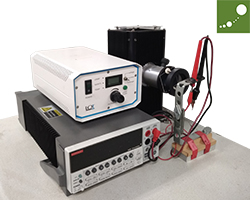

Battery Analyzer / Pil Performans Analizörü

Eight-channel battery analyser for galvanostatic charge/discharge tests for coin-cell and cylindrical batteries. Each channel has independent constant-current and constant-voltage source. Different working modes and functions can be set for each channel individually. Test reports provide different types of information/curves (voltage-time curve, current-time curve, capacity-voltage curve, etc).

Click to visit instrument website for technical specifications.

UV Ozone Cleaner / UV Ozon Temizleyici

The working principle of a UV Ozone Cleaner is that a mercury vapor lamp generates ultra-violet light and ozone resulting in the atomic cleaning of silicon, silicon nitride, glass, metals, ceramics and other materials. It can also be used for UV curing, UV patterning, sharpening AFM probes, ozone etching and more.

Click to visit instrument website for technical specifications.

Solar Sımulator / Güneş Simülatörü

Solar simulators are the devices that provide illumination approximating natural sunlight. The purpose of the solar simulator is to provide a controllable indoor test facility under laboratory conditions, used for the testing of solar cells, sun screen, plastics, and other materials and devices.

Click to visit instrument website for technical specifications.

Spın Coater / Döndürmeli Kaplama Cihazı

Spin coating is a procedure used to deposit uniform thin films to flat substrates. In our lab, we produced nanometer thick thin film coatings using the spin coating machine.

Click to visit instrument website for technical specifications.

Surface Processes

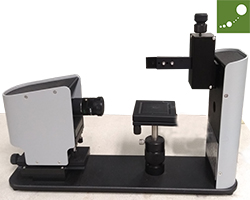

Optical Tensiometer (contact angle measurement) / Optik tansiyometre (Temas açısı ölçümü)

Dynamic and static contact angle measurements of materials are made with this device. At the same time, sequential image capture, dynamic video, surface tension and surface energy measurement are also performed. The contact angle, θ, is the quantitative measure of wetting a solid material with a liquid material.

Click to visit instrument website for technical specifications.

Ultrasonıc Atomızer

Ultrasonic atomizer is a powerful device for typical applications like homogenizing, emulsifying, dispersing, deagglomeration and wet-milling (particle size reduction), cell disruption and disintegration, extraction, degassing.

Click to visit instrument website for technical specifications.

Textile Printing and Finishing

Screen Printing / Serigrafi

Screen printing is a printing technique where a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil.

Padding Mangle / Fular

The padding mangle is used for dyeing and squeezing the fabrics after washing. The device in Temag Lab has vertical placed rollers in front of which there is dye vat having 350 mm width.

Click to visit instrument website for technical specifications.

Mini Stenter / Mini Ram

The stenter is used for drying and fixation of fabric samples after dyeing and washing. The drying time, temperature and air velocity are arranged according to the fabric or process specifications. The device in Temag Lab is capable of having maximum temperature of 250°C.

Click to visit instrument website for technical specifications.